E-Mobility Devices and Charging Safety in Domestic Applications

Underwriters Laboratory (UL) certification has become increasingly important for charging of e-scooters and e-bikes. Authorities emphasize the necessity for UL-certified products to enhance the safety of charging e-mobility devices. What is UL certification and why has it become crucial in creating a safer user experience?

UL Certification

Underwriters Laboratory is an independent organization in the United States that establishes safety standards for various products. These standards encompass a wide range of items—from raw materials used in appliance wiring to processes like water treatment to end products such as holiday lights.

UL is not a government entity and does not have the authority to enforce its standards on any company or industry. However, due to the rigorous testing involved in developing these standards, they are considered best practices by the industries and products they address. For instance, building codes often reference relevant UL standards. Recently, the New York City Council mandated UL standards for e-mobility chargers.

If a product causes harm, a company can be sued for damages. During the proceedings, the company can explain what went wrong and why they believed their product was safe. By manufacturing products that comply with the relevant UL standard(s), the company benefits from UL’s extensive testing, research, and proven experience in determining safe operation. Without UL compliance, a company’s defense relies solely on its own research and testing, which may be less comprehensive and more susceptible to challenge.

Charging e-mobility devices can be tricky.

Many e-scooter rental in the U.S. use gig workers (independent contractors who work flexible hours) to charge their scooters. Using an app, gig workers locate e-scooters that need charging, collect them, charge them at home from a domestic power source, and then return them to the streets once charged.

Many e-scooters are designed with swappable battery packs to enable quick returns to service. Rental companies pay for each recharged scooter put back into operation. This model often results in multiple scooters being charged simultaneously at the same location, typically in a domestic setting. Additionally, private owners of scooters or e-bikes also bring their devices indoors to prevent theft. Even when off-street parking is available, an internal power socket may still be used, often with an extension cable running outside.

Charging a single e-bike or e-scooter should not pose safety issues, provided wiring and breakers are up-to-code and adequate safety systems are used. E-scooters are designed to be charged from a regular 20A outlet, rated for a 16A continuous load. This rating is calculated by taking the continuous 16A draw and multiplying it by a factor of 1.25 to give 20A. A UL-compliant charger will only draw 16A continuously from a 20A circuit. A non-UL-rated charger might draw higher currents, which, when combined with multiple chargers on an extension cord, can easily lead to an overload situation.

Overloaded sockets can cause wiring to become damaged and degrade over time. High-resistance nodes can form either in the cable or at terminations, leading to a risk of fire. In multi-family dwellings, the risk is exacerbated if multiple e-scooters are being charged simultaneously, especially by someone charging multiple batteries for an e-scooter company.

Legislative Actions and Consumer Safety

In the USA, the Consumer Product Safety Commission (CPSC) now requires all retailers, importers, and distributors of e-mobility devices to comply with established UL safety standards, recognizing that consumers are not well-versed in safety issues or solutions. The New York City Council followed suit, passing legislation requiring all e-bikes, e-scooters, and personal mobility devices to be certified by either UL or another nationally recognized laboratory. Many apartment buildings in New York, including public housing, now require tenants to use only UL-certified chargers. These legislative actions have prompted e-mobility device manufacturers to educate consumers about UL safety standards by prominently displaying their UL certifications in advertisements and on websites.

Overloading batteries is the main cause of fires in battery electric vehicle (BEV) applications. According to a UL standards and engagement report from May 2024, around 50% of e-mobility device owners are unaware that their battery is lithium-ion. Although lithium-ion batteries have been around for 30 years and their behavior is well understood by the scientific and engineering communities, the public is less educated on how to use them safely. This lack of knowledge leads to behaviors that increase fire risk. The same report notes that 49% of e-mobility owners charge their device in a way that blocks the fire exit from their home. Users also habitually leave batteries on the charger after they are fully charged, group chargers together, charge overnight, or otherwise leave them unattended while charging, all of which increases the risk of battery fires.

UL standards help create a safe environment.

UL has over 80 standards addressing lithium-ion battery safety, with three directly related to lithium-ion batteries in e-bikes and e-mobility devices: UL2271, UL2272, and UL2849. These standards help reduce the risk of fires from thermal overload by developing rules for a range of critical features and operating conditions.

- UL2271: This standard sets requirements for the design, construction, and testing of battery packs in light electric vehicles (LEVs). It covers electrical, mechanical, and environmental tests to ensure batteries can withstand overcharging, over-discharging, short circuits, imbalanced charging, and safe operation at a defined maximum temperature. Batteries must not explode, catch fire, rupture, present an electric shock hazard, or lose any protection as a result of the tests. Protective circuits must have redundant features that continue to function in the event of power loss. This applies to aftermarket batteries as well as those originally installed in the LEV.

- UL2272: This standard focuses on the overall safety of the electrical systems of personal e-mobility devices. It sets standards for the design, construction, and testing of the device as a whole unit and tests the device for safety against electrical and fire hazards, as well as durability and stability. The electrical tests are similar to those in UL2271 but are applied to the whole system, not just the battery.

- UL2849: This standard is specific to the electrical systems of e-bikes. It covers the battery pack and the system as a whole, addressing the same range of safety issues experienced by other e-mobility devices. This standard does not cover aftermarket components, which is why UL2271 is also important for ensuring consumer safety.

UL 2849 addresses more than just the battery: the standard looks at a holistic electrical system approach to safety:

Battery Cell

- Electrical or environmental susceptibility

- Mechanical integrity

Battery Pack

- Prevention of fire propagation

- Battey management system functional safety

Electric Motor

- Material and electrical safety

- Control system functional safety

Battey Charger

- No electric shock or fire hazard

- Compatible to power requirement of the hose

Electric Bicycle

- Charging and discharging within battery limits

- Temperature within battery limits

- Susceptible to adverse conditions from application and environment

- Interrupt charging when error with host or charger

Power Integrations enables designs that meet UL charging standards.

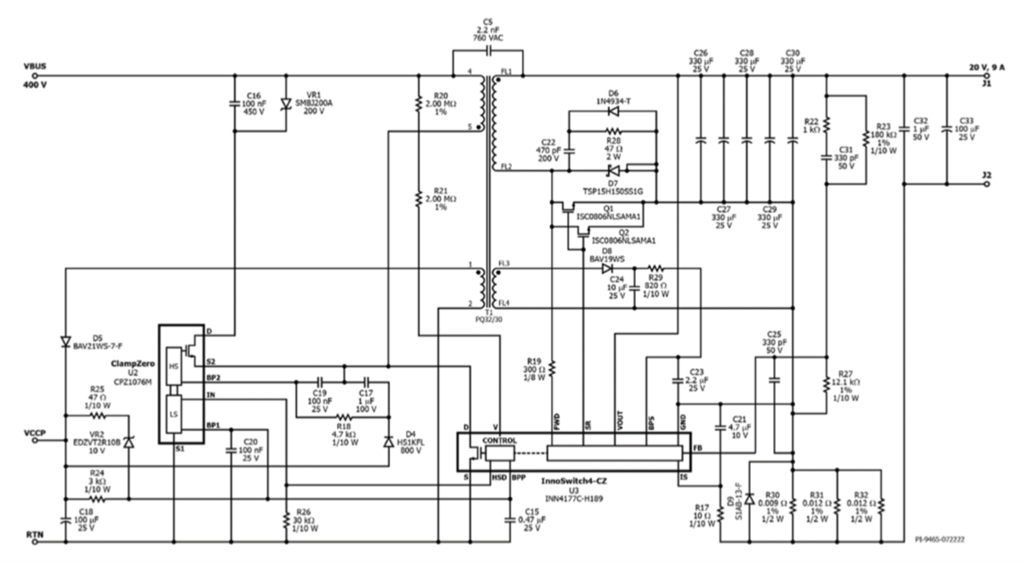

Power Integrations offers a range of highly integrated, high-voltage ICs for offline power conversion suitable for charging e-scooters and e-bikes. The design example, DER930, is a 180W, 20V, 9A power supply that uses three different Power Integrations products: InnoSwitch™4-CZ PowiGaN™ INN4177-H189, ClampZero™ CPZ1076M, and HiperPFS™-5 PFS5177F.

This design offers up to 95% efficiency at full load, reducing power loss as heat and keeping the solution cooler and more compact, which are key features for e-mobility solutions. Safety features include overvoltage protection, overcurrent protection, and integrated thermal protection. All these features are crucial for meeting UL standards for e-mobility designs.

Figure 1 – DER-930 Schematic, Flyback Section

Over-Temperature Protection

Thermal protection enables the charger to detect rising temperatures and take action to prevent a thermal event, such as a fire. The thermal shutdown circuitry senses the die temperature of the primary switch, interrupting switching when an over-temperature condition is detected. A large thermal hysteresis ensures that the charger returns to a safe temperature before switching is re-enabled. Different temperature responses are possible, including hysteretic recovery or latch-off (requiring manual cycling of the AC supply). The hysteretic response prevents the switch from turning back on until the temperature falls below a second, lower threshold. The latch-off response requires enabling the primary side by bringing the BP control pin below another threshold, achieved by cycling the AC mains supply.

Overvoltage, Undervoltage and Overcurrent protection

Output voltage protection employs a bias winding on the main transformer to drive current into the primary bypass pin of the InnoSwitch4-CZ IC. The voltage developed across the bias winding tracks the power supply output voltage. A Zener diode connected from the bias winding output to the primary bypass pin can reliably detect a secondary overvoltage fault and cause the primary-side controller to latch-off or enter auto-restart, depending on the selected fault response type.

The InnoSwitch4-CZ regulates the output current through an external current sense resistor between the ISENSE (IS) and secondary ground (GND) pins, where the voltage generated across the resistor is compared to an internal reference ISV(TH) (~35 mV).

Overvoltage and overcurrent protection enables the charger to manage operating conditions outside the desired envelope safely, protecting both the battery and the power conversion stage. By including these safety features in their devices, Power Integrations helps designers create robust and safe solutions quickly, reducing time to market and easing the task of meeting UL safety standards.

Conclusion

Safety standards, such as those created by independent companies like UL, are crucial tools for creating safe and reliable products. These standards not only protect consumers but also support manufacturers in building a strong market reputation, elevating the entire marketplace. Companies like Power Integrations, which design solutions with integrated safety features, help support the design community in advancing their designs, meeting the needs of an ever-developing market, and ultimately keeping consumers safe.