2SC0650P

Dual-channel SCALE-2 driver core with Planar transformers, highest integration level, highest power density for high-power and high-frequency, 50 A gate current and 2 x 6 W output power

Dual-channel SCALE-2 driver core with Planar transformers, highest integration level, highest power density for high-power and high-frequency, 50 A gate current and 2 x 6 W output power

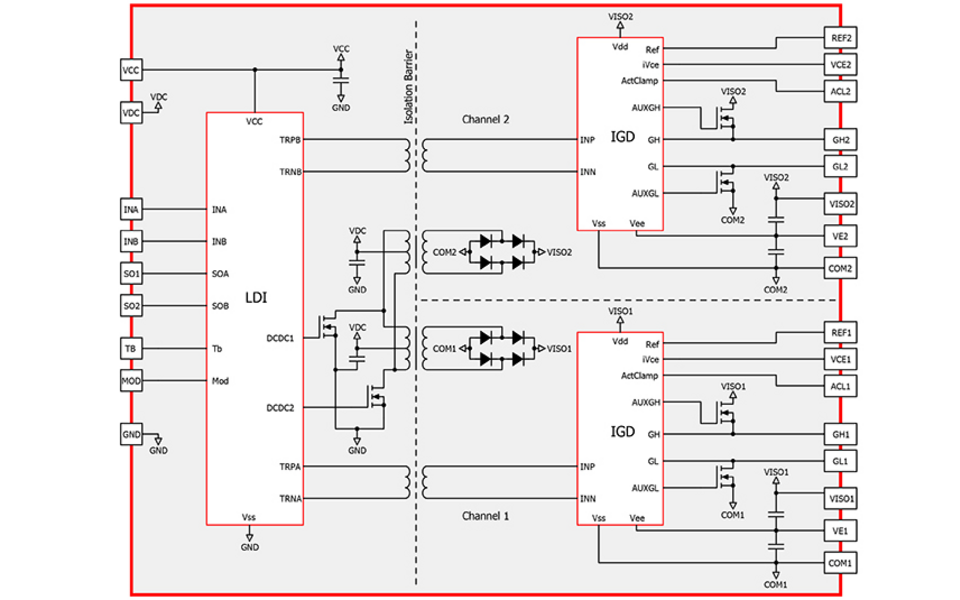

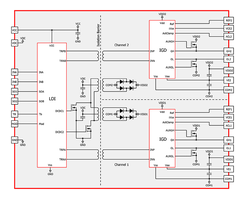

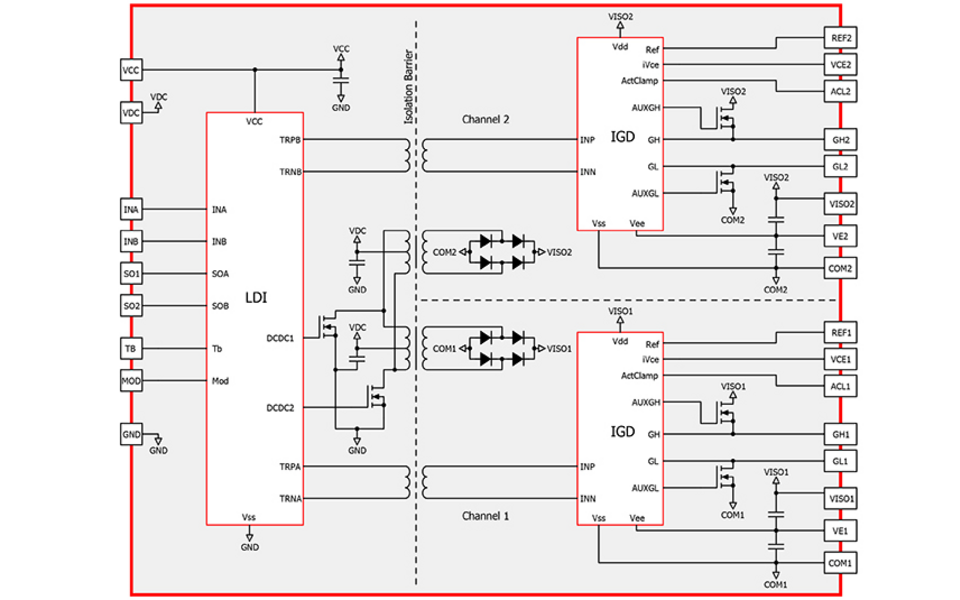

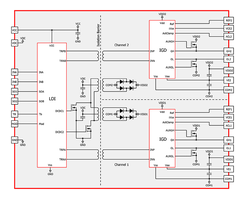

The 2SC0650P SCALE-2 dual driver core combines high power density with broad applicability. The driver is designed for both high-power and high-frequency applications requiring maximum reliability. It is suitable for IGBTs with reverse voltages up to 1700 V and also features a dedicated MOSFET mode. An embedded paralleling capability allows simple inverter design at higher power ratings. Multi-level topologies are also supported.

Advantages of the Technology

CONCEPT’s patented planar-transformer technology assures efficient and high-voltage isolation and long-term reliability and enables significant improvements in compactness, interference immunity and performance. Excellent EMC performance with a dv/dt strength of more than 100 V/ns allows safe and reliable operation in even the toughest industrial applications.

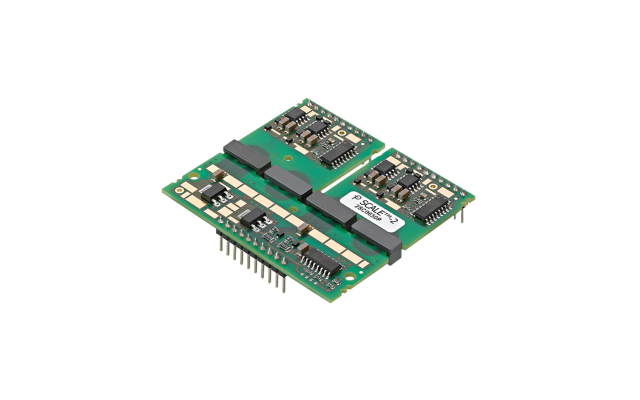

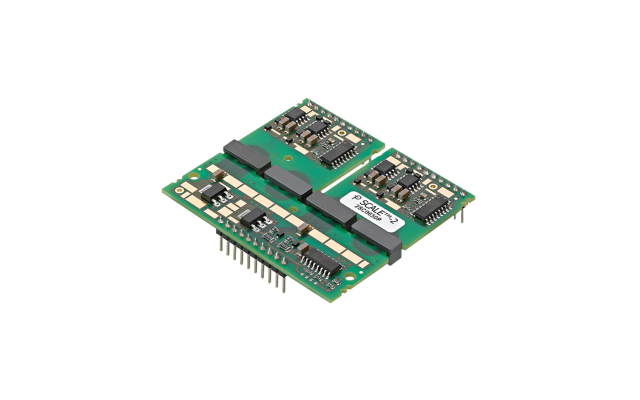

The 2SC0650P has a profile of only 6.5 mm and a footprint of 57 x 62 mm. The highly integrated SCALE-2 chipset reduces the component count by up to 85% compared to conventional solutions, thus significantly increasing reliability and reducing costs.

SCALE-2 technology also enables the driver core to operate at switching frequencies of up to 150 kHz – at best-in-class efficiency. The 2SC0650P combines a complete two-channel driver core with all components required for driving, such as an isolated DC/DC converter, short-circuit protection, Advanced Active Clamping as well as supply voltage monitoring. Each of the two output channels is electrically-isolated from the primary side and the other secondary channel.

IGBT Mode

An output current of 50 A and 6 W drive power is available per channel, making the 2SC0650P a suitable driver both for high-power modules and parallel-connected IGBT modules. In the dedicated IGBT mode, the driver provides a gate voltage swing of +15 V / – 10V. The turn-on voltage is regulated to maintain a stable 15 V regardless of the output power level.

Superior EMC with dv/dt of greater than 100 V/ns allows reliable operation even in the industry’s harshest environments. The 2SC0650P is suited for high-power IGBTs with blocking voltages up to 1700 V.

MOSFET Mode

A dedicated MOSFET mode is implemented in the 2SC0650P. It allows any gate voltage swing of +10 V…+20 V / 0 V to make the most of the driver’s 150 kHz switching speed.

With its high output power, very short delay, and extremely small jitter, the 2SC0650P driver core has been specifically designed for high-power and ultra-fast switching, fully exploiting the capabilities of state-of-the-art MOS power devices.

Benefits in Fast-Switching Applications

Fast switching not only requires high drive power and maximum frequency but also relies on tight control over crucial parameters such as the driver’s delay time and the associated jitter. A fast driver with a short delay introduces significantly less phase lag into the power system’s control loop. This is of great importance when maintaining the stability of the control loop as it allows the benefits of fast switching to be fully exploited.

The 2SC0650P shares the SCALE-2 performance figures for fast signal transmission delivering less than 80ns delay time and an extremely low jitter of less than ±2 ns. It is this combination of high output power and stable precision that makes the 2SC0650P a suitable choice for highly optimized systems, where tight control over timing margins is mandatory.

Driving Parallel-Connected IGBTs

The driver allows direct parallel connection of any number of IGBT modules with individual drivers. This new pioneering concept makes it practical for the first time to build a converter series with discrete modules as well as parallel-connected IGBTs without any significant additional development effort.

Use of planar transformer technology leads to low transformer stray inductance, ultra-flat design and extrem power density.